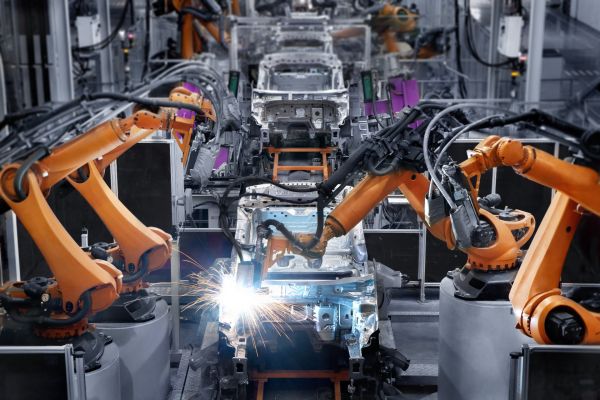

New research commissioned by Digital Catapult and Made Smarter Technology has revealed that the COVID-19 Pandemic might be a turning point when it comes to UK manufacturers implementing advanced technology such as AI, blockchain, the Internet of things or 5G.

Seventy-seven percent of respondent said that the pandemic has made their business more open to change and innovation.

However, despite recognising these technologies would benefit their manufacturing operations (71%), design and engineering processes (60%) and procurement and supply chain performance (49%), a third (32%) of senior manufacturers have admitted that the UK is behind its international competitors when it comes to adopting advanced technologies.

The new research revealed that they key barriers when it comes to accessing these benefits include a lack of budget, especially in light of the economic impact of the pandemic, with 40% saying it is stopping them investing. This was followed by cyber security concerns (32%) and a lack of skills within the company (30%).

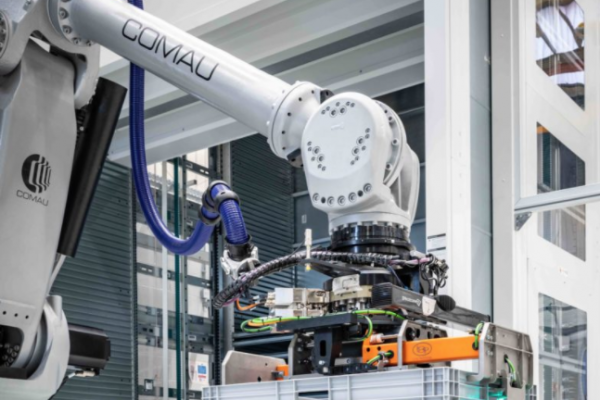

To help manufacturers overcome these hurdles, as well as fast-forward and shape the UK’s technology innovation directly into industry, the Made Smarter Technology Accelerator empowers established manufacturers to join forces with innovative technology start-ups and scale-ups to develop technology prototypes and minimum viable products in order to drive productivity, digitalisation and innovation and ultimately push forward the fourth industrial revolution for the UK manufacturing sector.

Digital Catapult has announced seven industry partners, including BAE Systems, Babcock International Group and Sainsbury’s, which have partnered with the match-funded Made Smarter Technology Accelerator programme and have set 14 challenges for the technology companies to respond to. The challenges range from increasing shelf life and sell through of products while reducing waste (Sainsbury’s) to scalable artificial intelligence for visual inspection (BAE Systems).

The seven partners joining the programme are:

- Babcock International Group

- BAE Systems

- GAF

- Northumbria Water Group (NWG)

- O’Neils Irish International Sports Company Ltd

- Safran Landing Systems and

- Sainsbury’s

The successful start-up and scale-up applicants selected to respond will be provided with up to £20,000 funding each and a platform to grow as they develop prototypes to address these challenges. In return for both match-funded financial and in-kind contributions, partners will gain direct access to the outputs and learnings of the programme as well as have proof of concepts developed for challenges they set.

Dr Jeremy Silver, CEO of Digital Catapult, said:

Navigating this year’s extremely challenging conditions has been tough for manufacturers of all sizes, right across the UK. Digital Catapult is dedicated to working hand in hand with industry and the UK’s vibrant tech start-up community, and it’s really encouraging to see so many organisations from the sector seize this opportunity to embrace innovation as an important means of building back better. The Made Smarter Technology Accelerator will make visible how a range of disruptive emerging technologies will really work to benefit early industrial adopters. It will also clarify routes to market for digital innovators. The outcomes from this programme are really positive, we will see new and traditional businesses working together – making enormous savings, significantly improving productivity, developing new business models, boosting exports and delivering on challenging net-zero targets.

Juergen Maier, Chair of Digital Catapult and Co-Chair of Made Smarter, added:

Our newly announced partners have set ambitious challenges, and the UK’s vibrant and diverse digital technology innovation community is incredibly well-placed to respond. By creating bonds between technology start-ups and scaleups and the manufacturing industry we have the opportunity for the UK to lead the way in the fourth industrial revolution – as advanced technology radically alters, and improves, the way we approach manufacturing.